ALCOHOL BASED ZIRCON COATING

The product

COTPOL 100A is a pure white zirconium silicate based coating, for use on the lightest to heaviest steel casting, grey, nodular and alloy irons.

It has a solids content of 75 % and a density of approx 2.1 kg/L

Advantages

| FEATURES | BENEFITS |

| Premium grade raw materials | Best and most consistent mould/core protection |

| Low binder content | Minimum gas evolution, high Refractoriness |

| Brush, swab and spray application | Versatile |

Application

Cotpol 100A is suitable for use on moulds and cores produced in all conventional resin binder systems. The coatings should be mixed thoroughly before use or before further dilution with IPA.

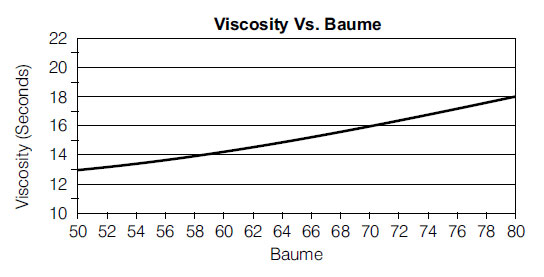

It is recommended that the consistency of the coating be checked by means of a flow with 4mm orifice or, alternatively, a Baume gauge. The approximate relationship between the two techniques is shown in the graph below.

The primary objective of both these methods is to control the coating layer thickness on the sand surface. Typically a wet coating layer of between 0.1mm - 0.3mm should be obtained depending on the casting weight, section and pouring temperature.

For guidance

Dip / Spray - Viscosity 13 -15 sec., Baume 50 - 68

Brush / Swab -Viscosity 16-20 sec., Baume 6 0 -70

Please note

Castings produced with Manganese steel alloys prone to reaction with silicate will require the use of magnesite or olivine based coatings.

PHYSICAL DATA (TYPICAL)

Specifications

| PROPERTY | |

| COLOR | WHITE |

| SOLIDS | 75% |

| DENSITY AS DELIVERED | 2.1 KG / LITRE |

Packaging

50 kg HDPE Polycarboys